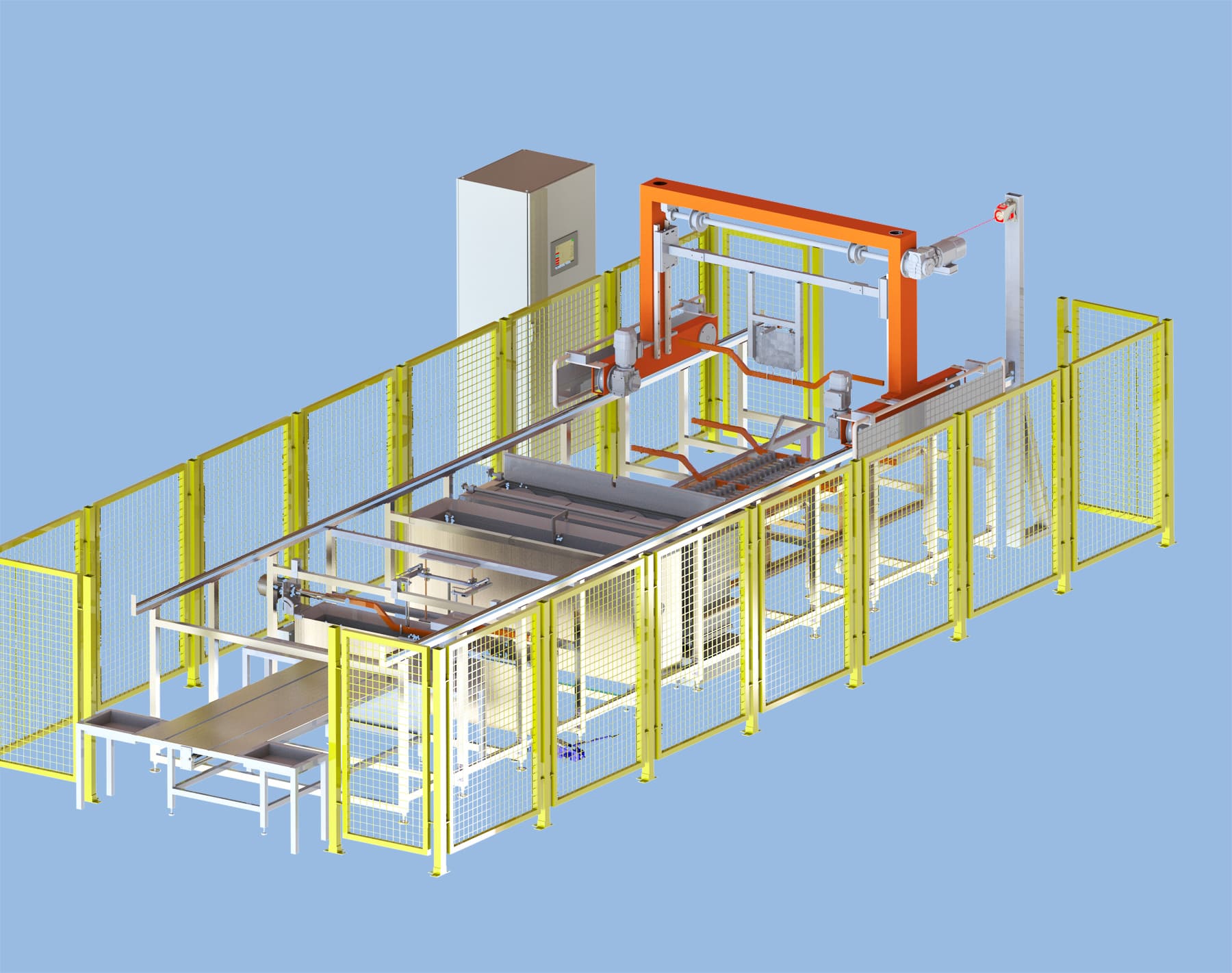

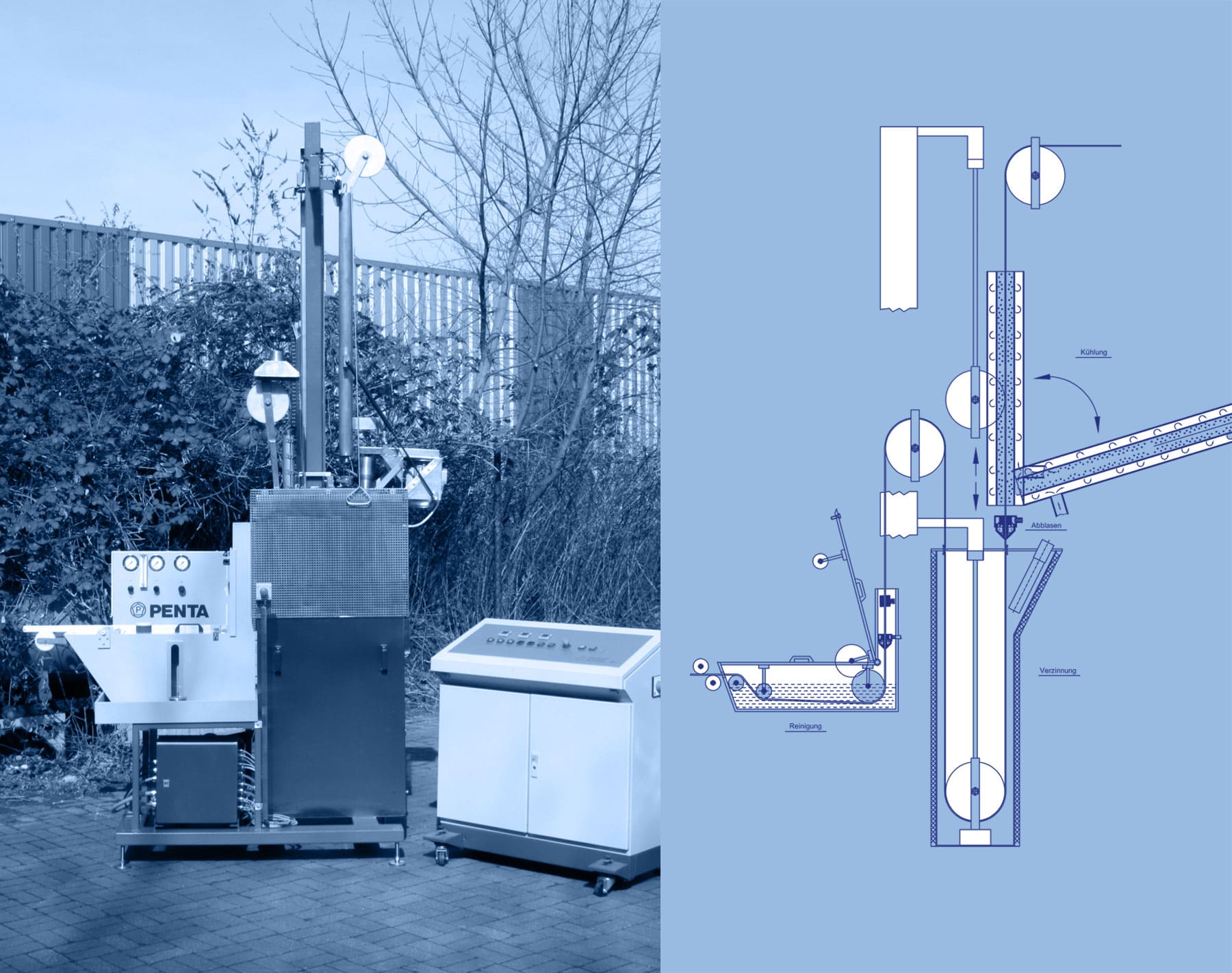

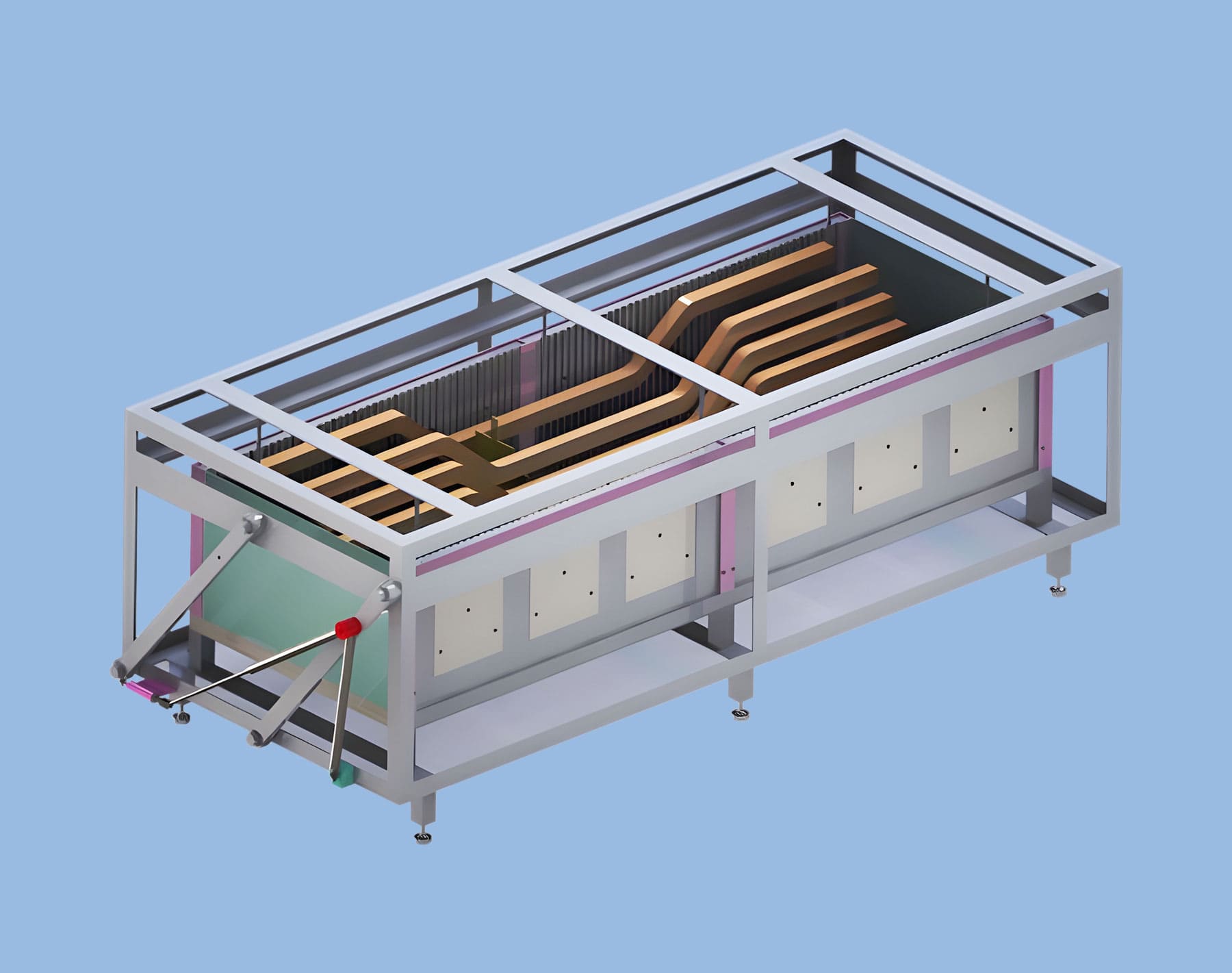

With our wire tinning plant, high-frequency cables with copper braiding can be tinned in a continuous process. This ensures optimum shielding of the cables. The systems consist of a pre-cleaning station, a heated tin bath with circulation pump and a blow-off and cooling unit. Electrical control of all functions ensures reliable and uniform application of the tin.

The focus in the development of the wire tinning systems was on good efficiency. The systems can be operated at a maximum throughput speed of 40 meters per minute. Of course, the systems also meet our standards in terms of user-friendliness, safety and durability. The first systems were delivered to the Nuremberg and Shanghai sites of the Nexans Group in 2005 and are still in operation.