Penta

Spector

Smarter HAL Inspection with AI

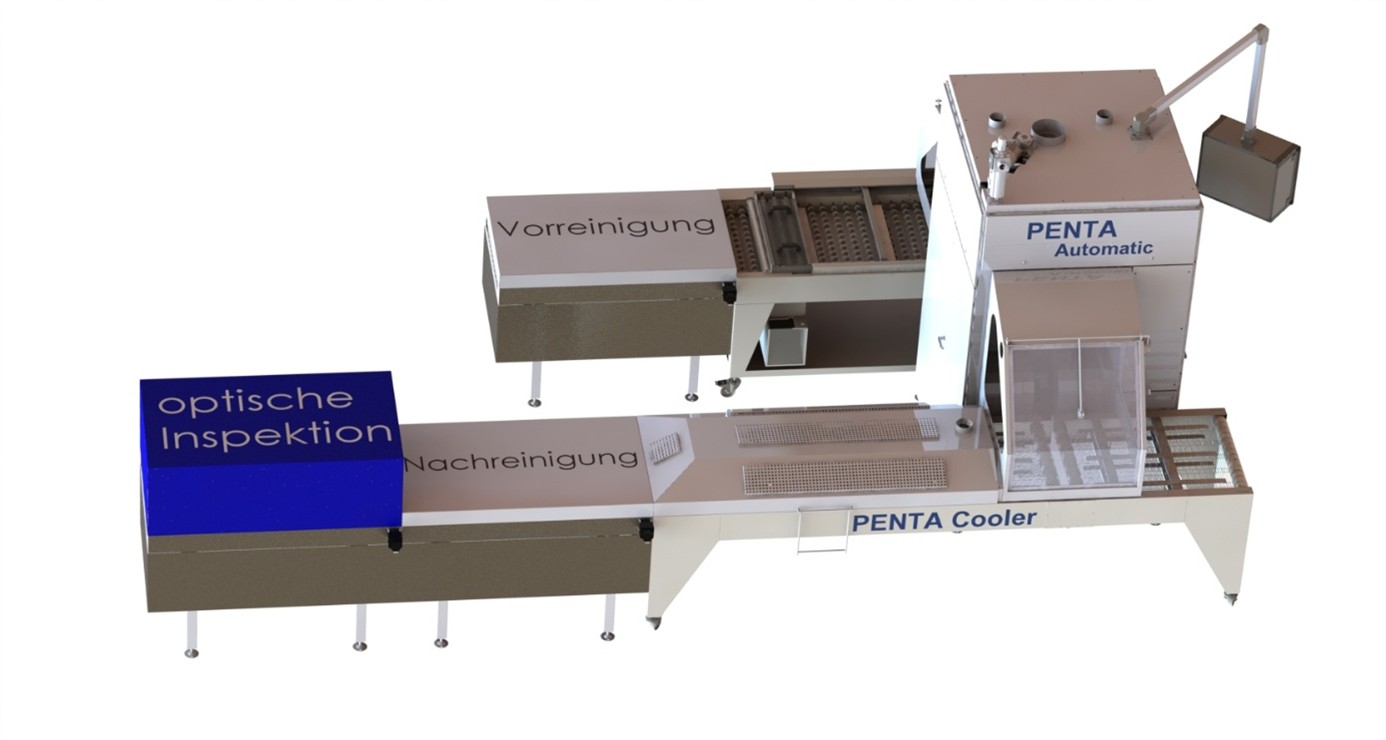

Together with the Chair of Reliability Technology and Risk Analysis (LZR) at the University of Wuppertal, Pentagal is developing a system for the optical inspection of bare PCBs directly after Hot Air Leveling. The Penta Spector is designed as an inline system (see diagram).

Production line with integrated Penta Spector AI inspection module.

Without complex test planning, the AI-supported inspection system detects typical Hot-Air Leveling defects in real time, significantly reducing scrap costs. The AI model, developed specifically for a research project, enables early system shutdown by reliably evaluating visual defects and digitally networking the modules. Representative studies ensure robust, generalised detection based on machine learning. In contrast to conventional AOI, this has minimised the pseudo-error rate (or false positives). Typical errors include, for example:

- Streaking

- Passive and non-tinned pads

- Blown-out holes

The system is designed so that it can not only be purchased in combination with new Hot Air Leveling systems, but can also be integrated into existing HAL systems.

The advantages lie in the optimisation of the production process, quality assurance and cost reduction through early fault detection before the assembly process, as well as savings in personnel costs.

The project is funded by the Federal Ministry for Economic Affairs and Energy.

PENTAGAL

Chemie und Maschinenbau GmbH

Carolinenglückstraße 35

44793 Bochum / Germany

Phone: +49 234 / 52 32 37

Fax: +49 234 / 52 29 89