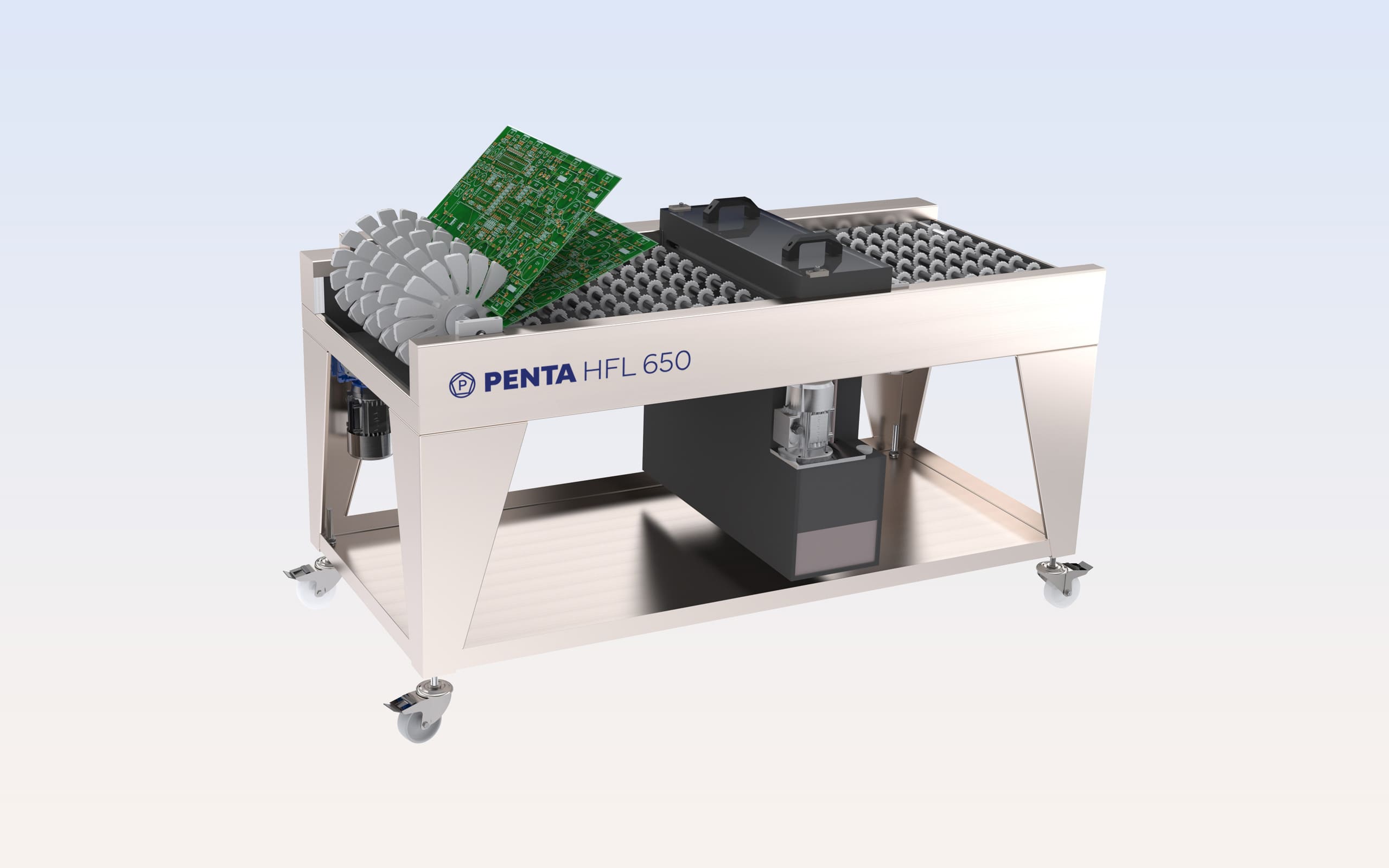

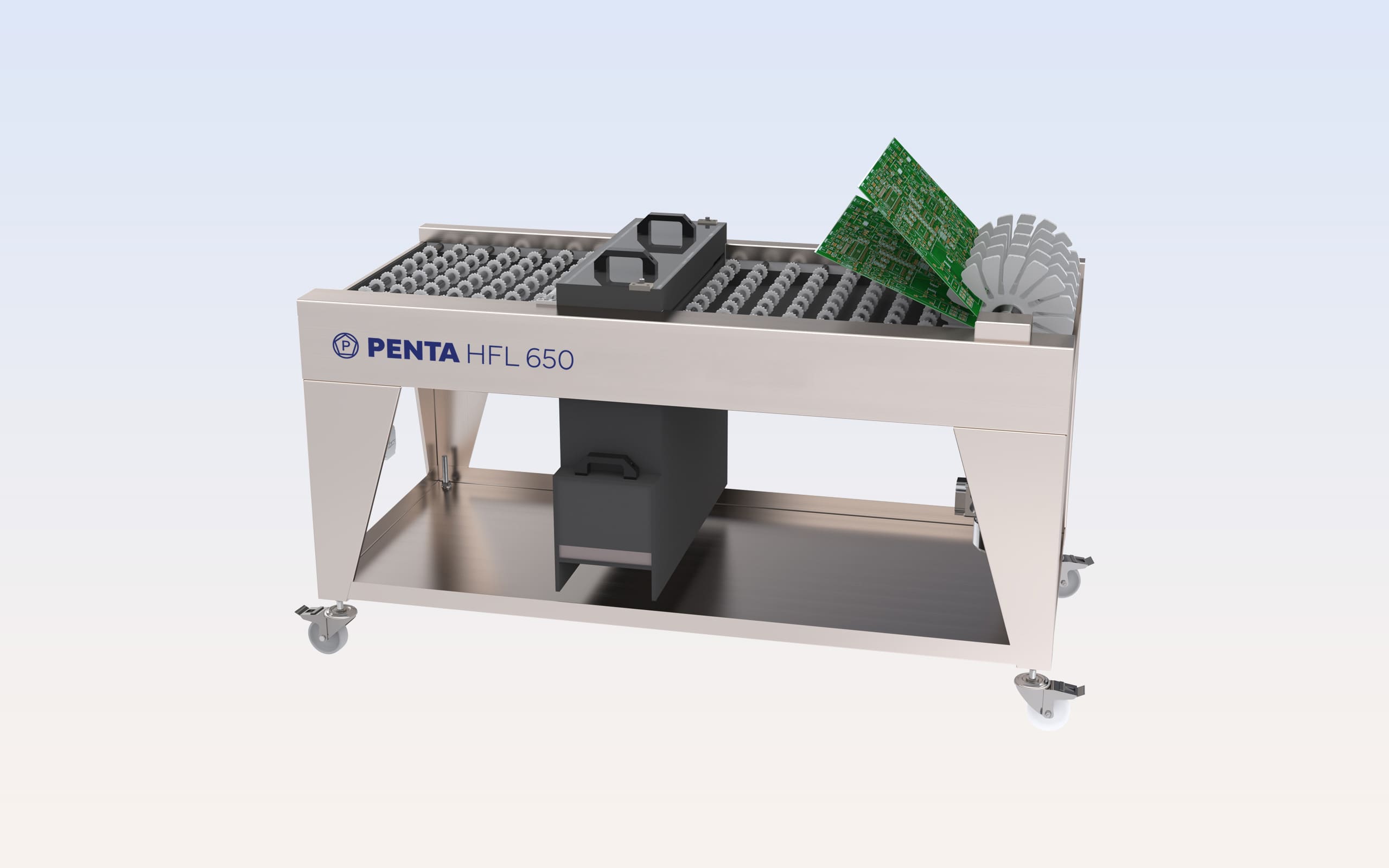

PENTA HFL 650 S

Flux station

The body of PENTA fluxer is made entirely of stainless steel, while the wet tank is made of plastic. The fluxing station is equipped with a speed-controlled belt drive that is adjustable up to 5 m/min. The pump is made of titanium, Teflon and PE1000. The stacker with special profile ensures the safe positioning of all panel formats. Thanks to the non-contact laser sensor system, there is no interference from flux. The flux level is monitored and can be automatically refilled as an option. The PLC-controlled process guarantees high flexibility and safety. The fluxer is available in various sizes.

Technical features

PENTAGAL

Chemie und Maschinenbau GmbH

Carolinenglückstraße 35

44793 Bochum / Germany

Phone: +49 234 / 52 32 37

Fax: +49 234 / 52 29 89