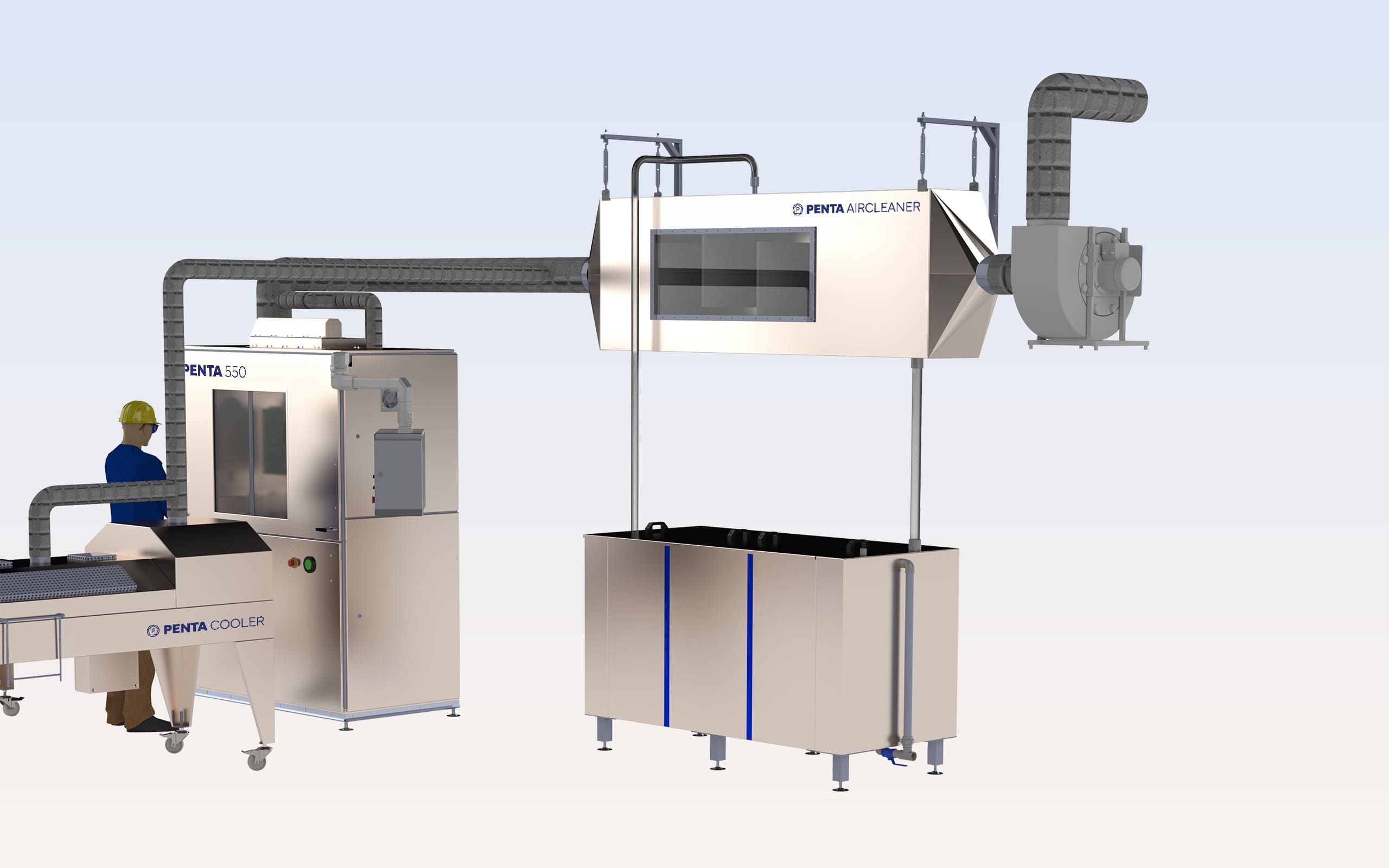

PENTA AIRCLEANER

Penta Air Cleaner can be ordered as a standard air washer suitable for Penta 550, Penta 580, Penta Automatic and other HALS, or individually adapted to your requirements in almost any size and air capacity. The standard version of PENTA Air Cleaner consists of a 2500 x 850 x 400 mm body made of 1.5 mm stainless steel sheet with a viewing window at the front to check the function.

The inlet and outlet opening is an R 200 - R300 mm flange connection for connection to the HAL and to the suction exhaust fan (optional order). Inside the air washer there are labyrinth chambers with PP fillers. A droplet separator and a spray pipe system for rinsing the packing are integrated. The water sprinkling/rinsing takes place via an inlet connection (top) R3/4".

The water drain connection on the underside is R11/4". Water from the neutralization system or a sedimentation tank system is recommended for rinsing. The power of the required submersible pump is between 0.5-1.0 kW depending on the delivery head.

Features

PENTAGAL

Chemie und Maschinenbau GmbH

Carolinenglückstraße 35

44793 Bochum / Germany

Phone: +49 234 / 52 32 37

Fax: +49 234 / 52 29 89